RECENDT - Research Center for Non-Destructive Testing GmbH

RECENDT - Research Center for Non-Destructive Testing GmbH

The Research Center for Non-Destructive Testing GmbH (RECENDT) provides services throughout the whole R&D process chain: from application-oriented fundamental research to the development of state-of-the-art technology for industrial applications. RECENDT implements customized, high-tech solutions for contactless sensing, material characterization, process-analytics and non-destructive testing. We provide measurement and characterization services and develop in-line sensing solutions for basically all industrial branches and we cooperate with multi-national enterprises and with SMEs equally.

Altenberger Straße 69

Linz

4040

Austria

48.33581892270675

14.32328562698158

Dipl.-Ing. Robert Holzer

+43 732 2468 – 4602

robert.holzer@recendt.at

www.recendt.at/en

Services

development of solutions for non-destructive and contactless sensing, testing and materials characterization

Equipment / infrastructure

RECENDT relys on a team of about 40 researchers with long-standing experience in the application of potonic technologies for contactless and non-destructive sensing in various industrial branches. Expertise is provided in the following technologies: LUS (Laser-Ultrasound), PCA (Physical and Computational Acoustics), NIR (Near Infrared) and Raman Spectrosopy, OCT (Optical Coherence Tomography) and THz (Terahertz) technologies (imaging and spectroscopy).

All groups have latest equipment available (optical benches and components, laser light sources, interferometers, sensing devices, Laser-Ultrasonic equipment, various OCT systems, various spectrometers and spectroscopic equipment in all wavelenght ranges and for Raman spectroscopy, (infrared spectroscopic) microscopes, THz-sources, THz-cameras, dryers, robots, SW-tools, high-performance computing infrastructure, electronics and software develoment suites) and perform their work in dedicated laboratories located in Linz at the campus of JKU (Johannes Kepler University).

Best practices / case studies of cooperation

RECENDT is since 2010 providing various developments and solutions for many industrial branches.

PAC – The research network

Process Analytical Technologies (e.g. Infrared Spectroscopic Methods) are able to monitor chemical processes inline and control them precisely, which enables perfect optimization. We have conducted intensive research in this field since 2010 and can act as your contact point to the entire research network PAC - www.k-pac.at

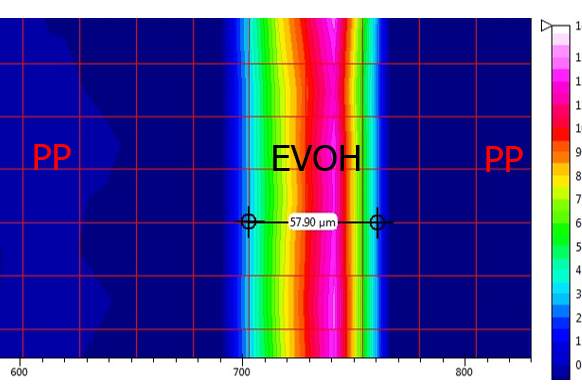

Spatially resolved spectroscopy

Do you want to know the exact local distribution (in micrometer range) of your chemical components? With Mid-Infrared-Microscopy we can chemically characterize and measure materials and cross-sections (e.g. residues or inclusions) with a spatial resolution as small as 5 µm.

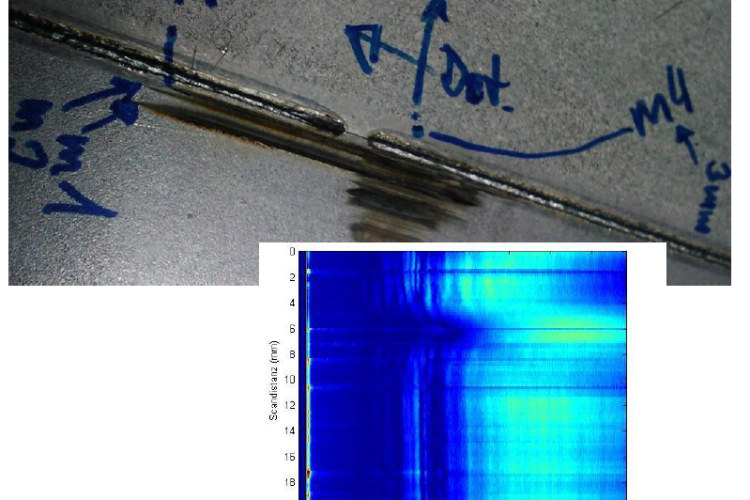

Inline quality assurance in welding

Non-destructive testing of welds is possible with Laser-Ultrasound. Thanks to the good automation capacity also inline measurements at high speed can be carried out, depending on the required resolution. With a repetition rate of 10 Hz, 100 Hz or even higher, flaws, inclusions, hot cracks and pore concentrations can be found.

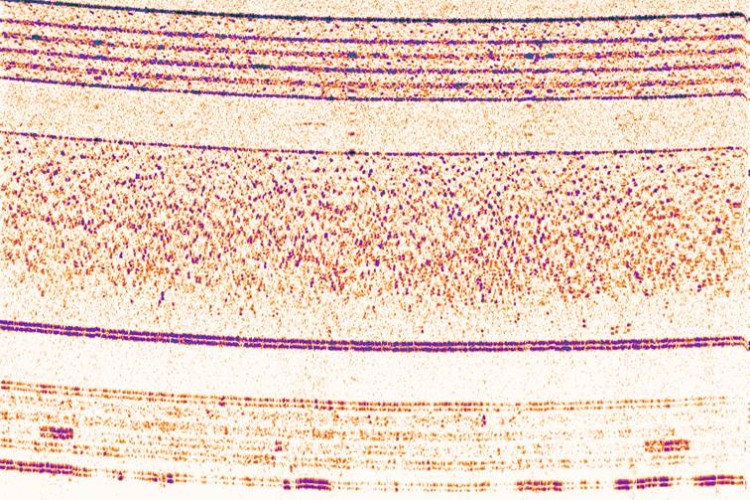

Hardness penetration depth in steel

The determination of the hardness penetration depth in thermally hardened components is essential for quality control. State-of-the-art is to cut samples and do etching and hardness measurements. Laser-Ultrasonics opens a non-destructive alternative. Thereby, zones of different microstructures at arbitrary positions can be imaged up to a tomographic representation of the hardness penetration depth.

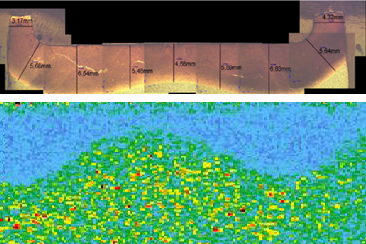

Visualization of multilayer structures

As illustrated in this example of an organic photovoltaic cell, multilayer structures can be measured and analysed with OCT (Optical Coherence Tomography). Organic PV-cells consist of organic semiconducting materials, transparent electrodes, and a protective coating. As a result of this, a homogeneous layer structure without defects, inclusions etc. is relevant for the quality, functionality, and long-lasting performance of the product.

Keywords

customer specific R&D services, in-line contactless sensing, PAT process-analytical technologies, NDT non-destructive testing, in-situ measurement